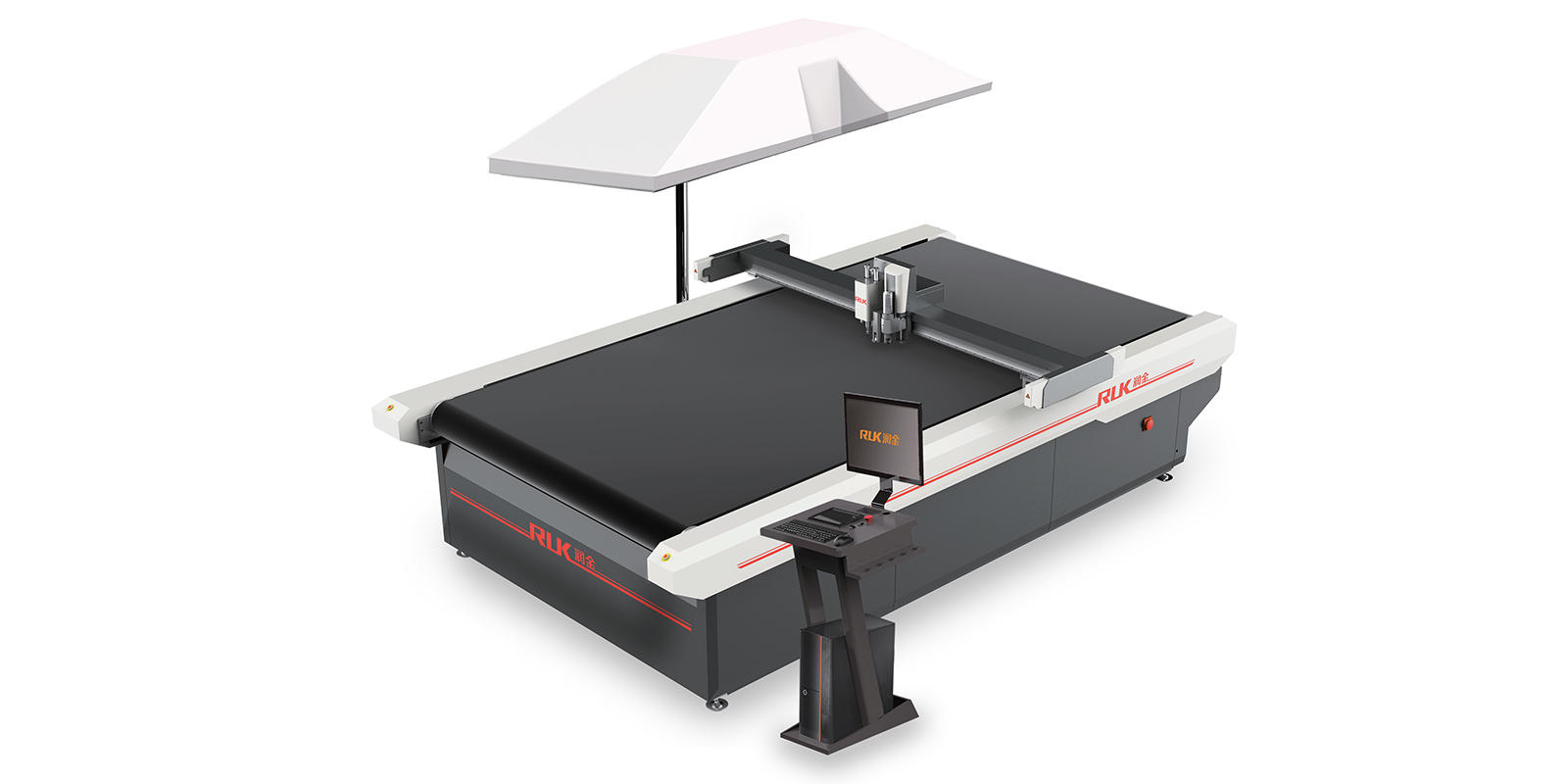

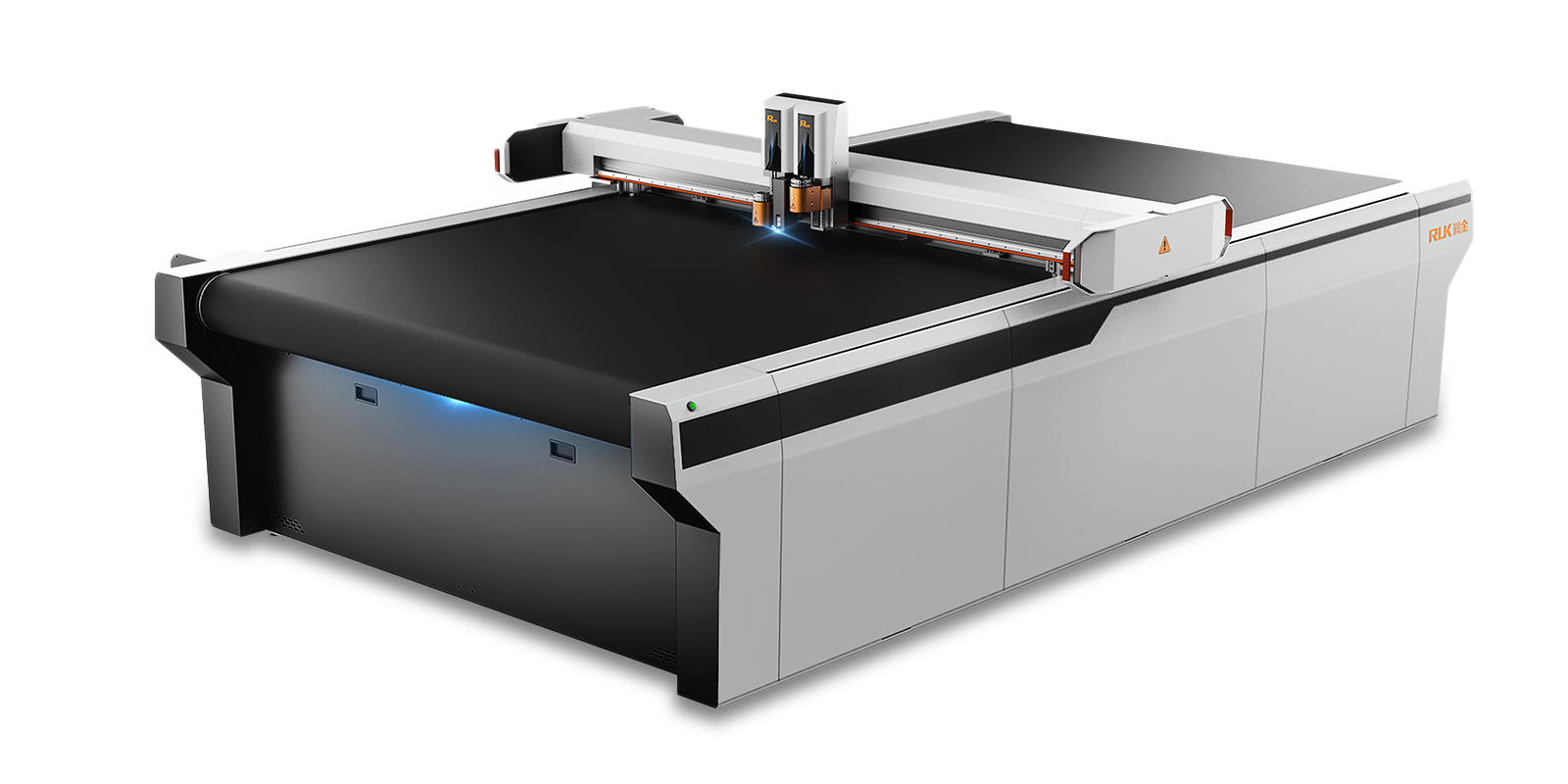

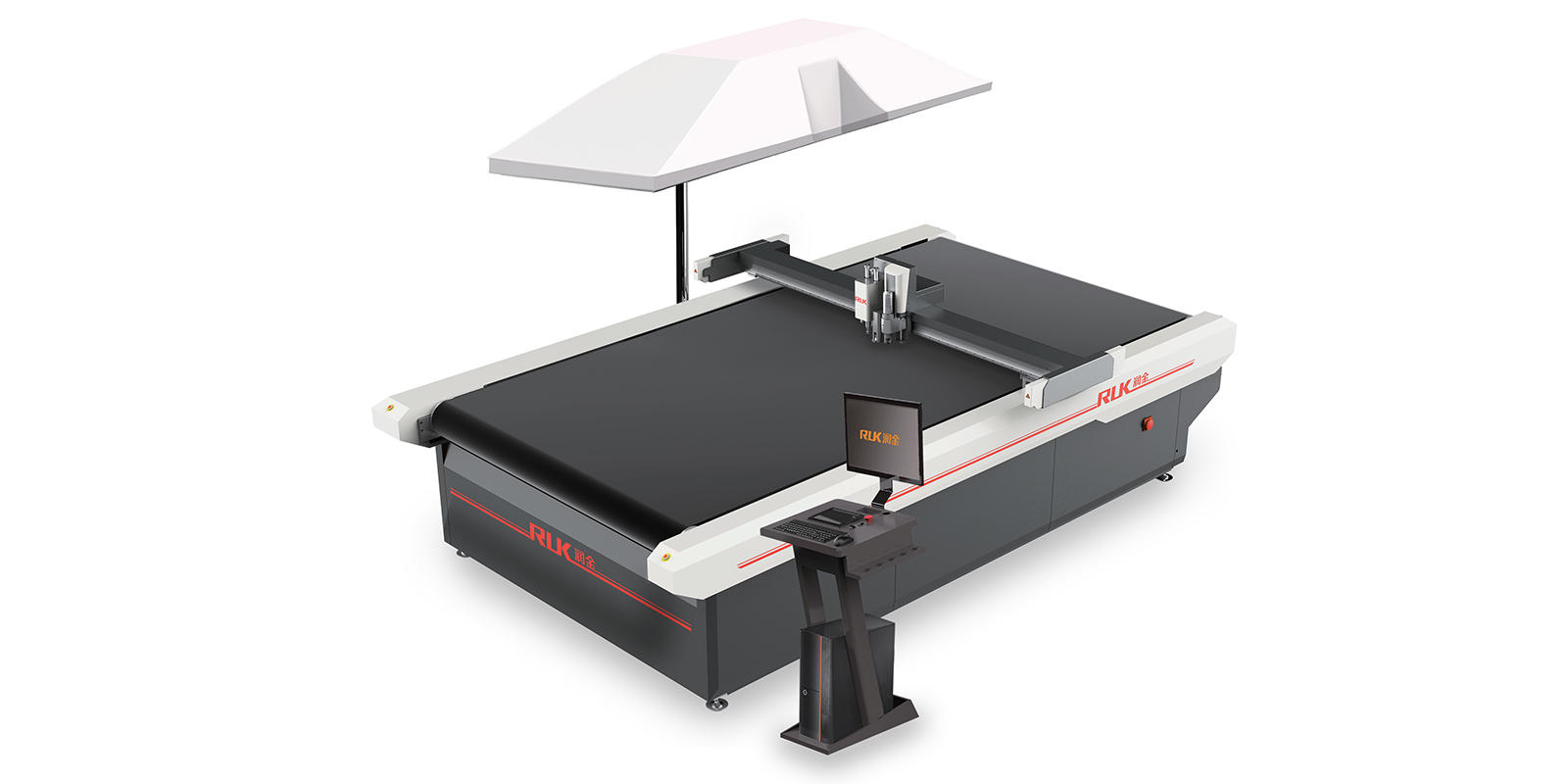

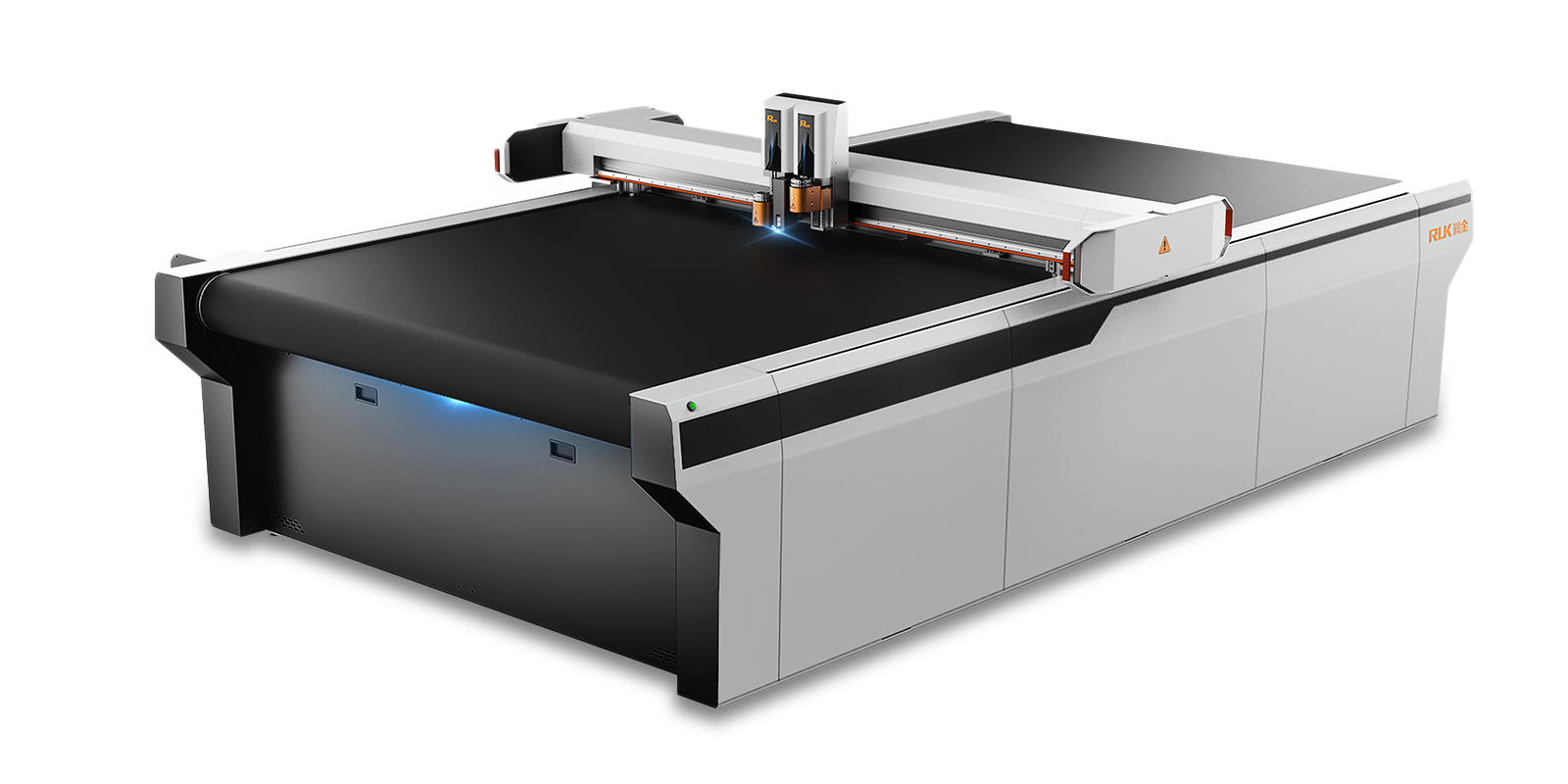

Professional Flexible Materials Automated Cutting Solutions.

10F, Bulijie Building, No.579, Rili Middle Road, Yinzhou District, Ningbo, Zhejiang, China.

Tel: +86-18657420197

Email: [email protected]