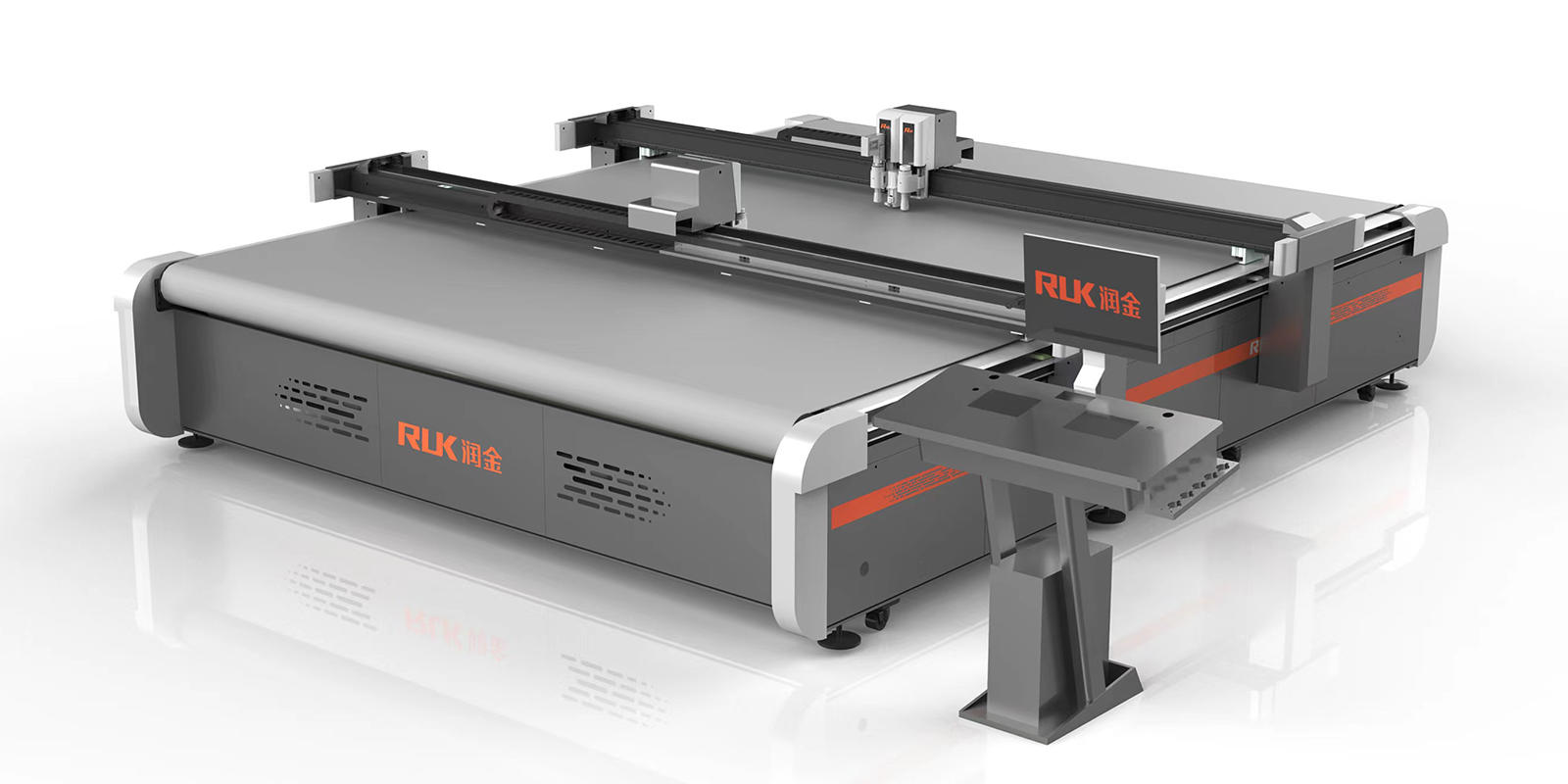

Professional Flexible Materials Automated Cutting Solutions.

1. Analysis of the single-double beam switching function

The single-double beam switching function is an innovative function designed by Flatbed Cutting Machine to adapt to different materials and different processing requirements. In single-beam mode, Flatbed Cutting Machine only uses one beam to support the cutting head for operation. This structure makes the equipment more flexible and faster when cutting with light loads. In double-beam mode, Flatbed Cutting Machine uses two beams to work together to support the cutting head, thereby enhancing the stability and load-bearing capacity of the equipment, which is suitable for cutting heavy materials or complex graphics.

Specifically, the single-double beam switching function is usually implemented through software control. Users only need to make simple settings on the software interface to quickly switch beam modes. At the same time, some advanced Flatbed Cutting Machines are also equipped with an intelligent recognition system that can automatically adjust the beam mode according to the thickness and hardness of the processed material, further improving the intelligence level of the equipment.

2. How does the single-beam and double-beam switching function increase operational flexibility?

The single-beam and double-beam switching function enables the Flatbed Cutting Machine to easily handle materials of different thicknesses and materials. When cutting thin materials, such as sticky notes and mask films, the single-beam mode provides sufficient flexibility and speed to ensure cutting accuracy and efficiency. When processing heavy materials, such as foam boards and cardboard, the double-beam mode ensures cutting stability and accuracy to prevent deformation or damage of the material during the cutting process.

Depending on the processing task, choosing the right beam mode can significantly improve cutting efficiency. When cutting light loads, the single-beam mode completes the cutting task at a faster speed and shortens the processing cycle. When cutting heavy loads, the double-beam mode provides stronger stability and load-bearing capacity, ensuring cutting quality while improving production efficiency.

The double-beam structure not only enhances stability, but also optimizes the space utilization of the equipment. Through reasonable beam layout and structural design, the double-beam Flatbed Cutting Machine can freely move the cutting head in a larger range to meet the cutting needs of large-size materials. At the same time, the double-beam structure also provides more cutting path options, making the equipment more flexible and free when cutting complex graphics.

The single-double beam switching function is usually implemented through software control. Users only need to make simple settings on the software interface to quickly switch the beam mode. At the same time, Flatbed Cutting Machine also supports remote control and automated operation, further improving the intelligence level and operational convenience of the equipment.

The single-double beam switching function enables Flatbed Cutting Machine to be applied to more fields and industries. For example, in the fields of clothing and textiles, home furnishings, bags and shoes, Flatbed Cutting Machine can be used to cut cloth, leather and other materials; in the fields of automotive interiors and leather products, Flatbed Cutting Machine can be used to cut automotive parts such as seat covers and steering wheel covers. In addition, Flatbed Cutting Machine can also be used in advertising production, packaging design and other fields, bringing users more business opportunities and profit space.

Ningbo Ruking Intelligent Technology Co., Ltd. Room 402, 4th Floor, Building 12, Xinchanyungu Industrial Park, Jiangkou Street, Fenghua District, Ningbo City, Zhejiang Province

Tel: +86-18167226377

Email: [email protected]

Copyright © 2023 by Ningbo Ruking Intelligent Technology Co., Ltd. Rights Reserved.

China Digital Cutter manufacturers Custom Digital Cutter Suppliers