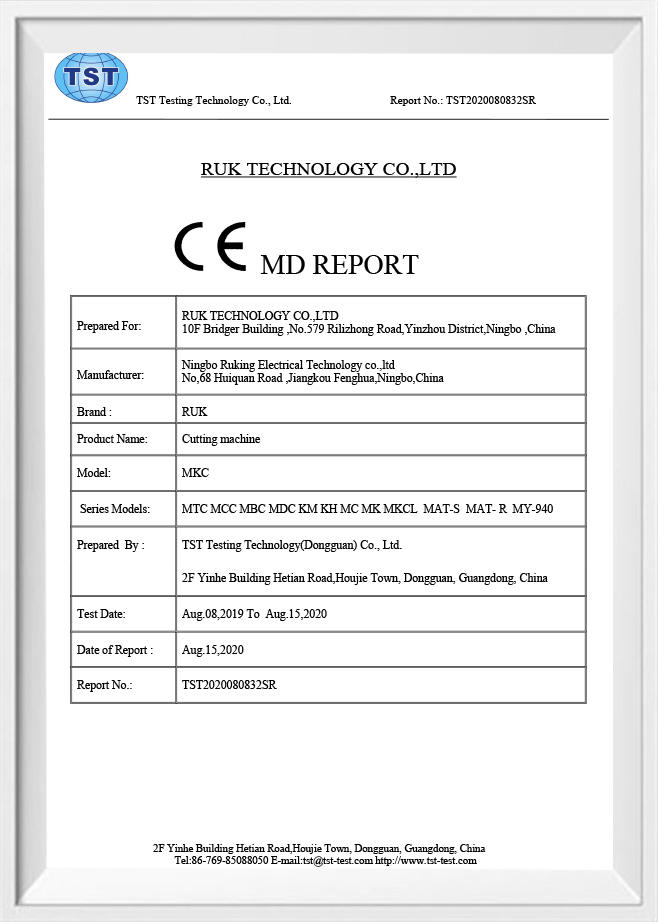

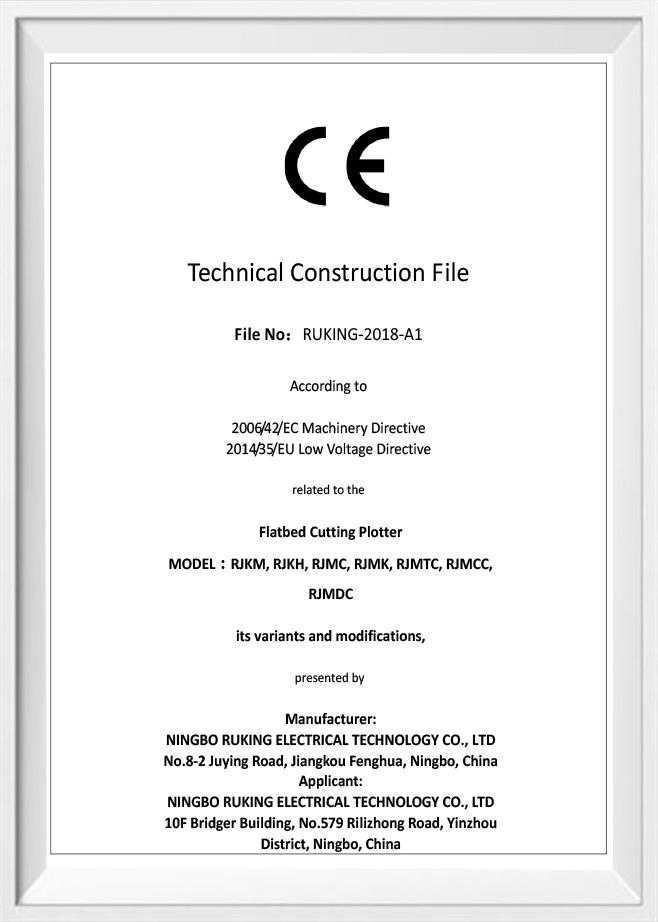

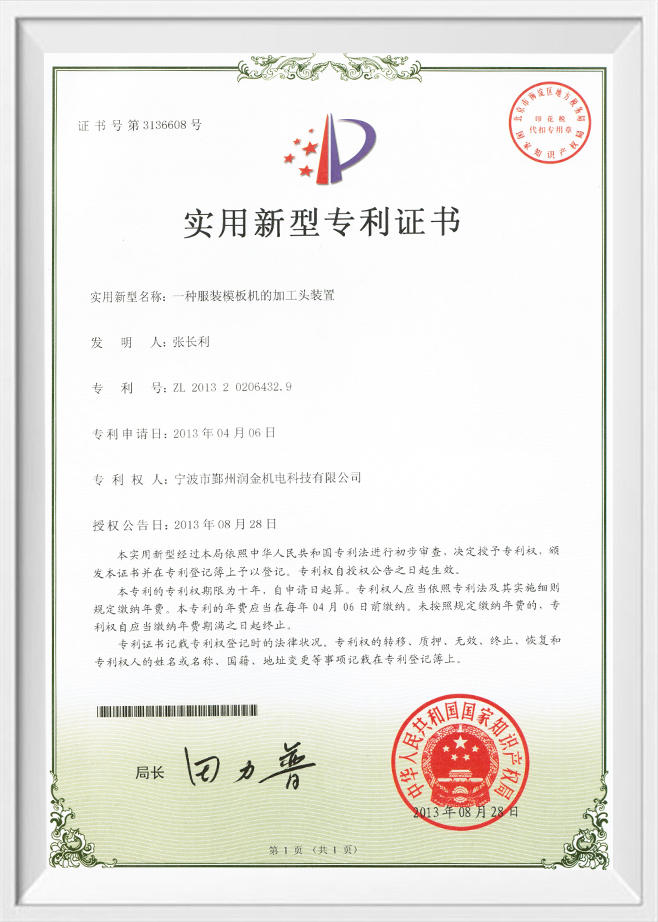

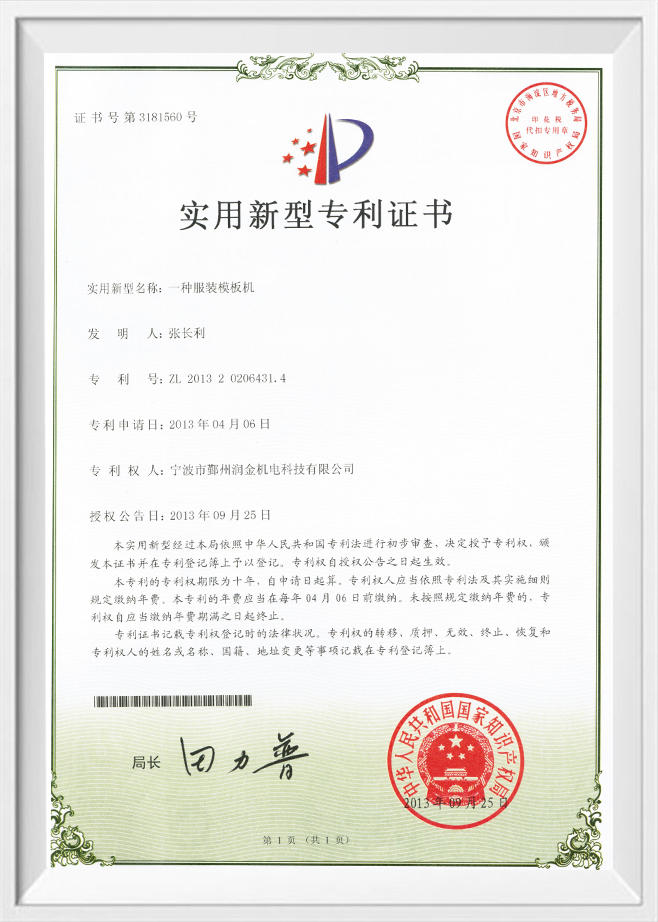

Ningbo RUKING Electrical Technology Co., Ltd is MTC06-2516 Advertising Graphics Automatic Cutting Plotter High-Speed CNC Cutting Machine Manufacturers and MTC06-2516 Advertising Graphics Automatic Cutting Plotter High-Speed CNC Cutting Machine Suppliers,a high-tech enterprise engaging in Industrial automation system, equipment and related spare parts, as well as its full set of program’s R&D, manufacturing, sales and service.RUK Tech owns a professional team consisted of competent and integrity people, who hold an important post on respective dept, machinery, electronics, computer software and management. We also have cooperation in program’s R&D with well-know university domestic and overseas, especially bringing in Europe’s technology and experts. We independently researched and developed CAD/CAM integrated NC cutting system, as well as controller and driving demanded in automation field.

Unrivalled performance and precision: The MTC series digital cutting systems are based on the most flexible, adaptable and easily expandable machine concept on the market.

English

English Français

Français русский

русский Español

Español